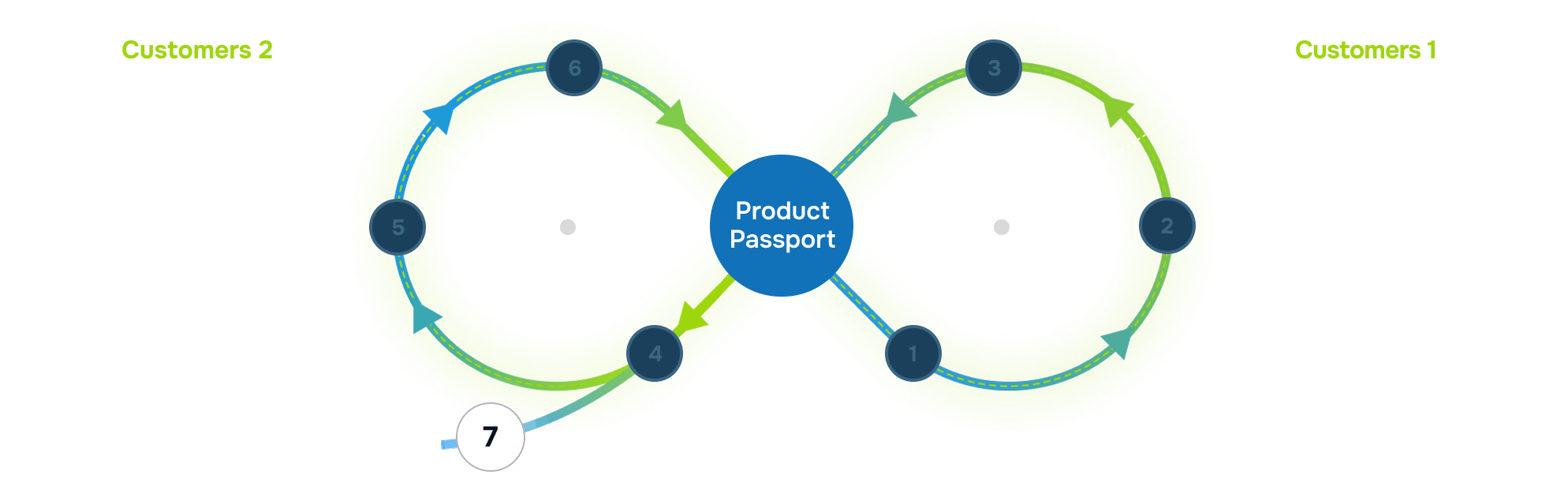

STEP 7

Back to Inventory

Back to Inventory refers to the process of reintegrating returned, refurbished, or repurposed assets into active inventory for future use, resale, or redistribution. This ensures maximum asset utilization, cost efficiency, and waste reduction.

1. Key Steps in the Process

- Reverse Logistics Handling – Receiving and processing returned products.

- Quality Inspection & Sorting – Evaluating condition and usability.

- Refurbishment & Repackaging – Restoring products for resale or redeployment.

- Inventory Optimization – Reallocating assets based on demand and supply needs.

2. Business Benefits of Back to Inventory

- Cost Savings – Reduces the need for new production.

- Sustainability – Lowers e-waste by extending product lifecycles.

- Supply Chain Efficiency – Enhances inventory forecasting and management.

How Tallgrass.ai Enhances Back to Inventory

Tallgrass.ai’s Revlogix platform enables:

- AI-driven asset valuation & lifecycle tracking

- Automated decision-making for reintegration

- Real-time inventory optimization

This ensures faster redeployment, reduced costs, and a sustainable supply chain strategy.